In an era where efficiency dictates success, businesses are searching for ways to minimize expenses without sacrificing quality. A robotics engineering company in Alabama provides cutting-edge automation solutions that streamline operations, reduce waste, and enhance productivity. Companies investing in robotics are seeing significant cost reductions, making automation an essential tool for staying competitive.

Robotics Expertise Quietly Eliminates Costly Human Errors in Production

Even the most skilled workforce can make mistakes, and in manufacturing, those errors often lead to wasted materials, delays, and expensive rework. Automation through robotics eliminates inconsistencies by executing tasks with precision, ensuring every product meets exact specifications. When an Alabama robotics engineering company designs systems for a facility, it minimizes human involvement in repetitive and intricate tasks, reducing the chance of defects.

A robotics engineering company in Alabama integrates machines that follow programmed instructions without deviation. This level of accuracy prevents costly errors such as misaligned parts, incorrect assembly, or inconsistent measurements. Businesses that rely on robotics in production lines experience fewer recalls, lower defect rates, and improved customer satisfaction—all of which directly impact the bottom line.

Precision Automation Shrinks Waste, Amplifying Profit Margins

Raw materials are among the biggest expenses in production, and any amount wasted chips away at profits. Robotic automation ensures that materials are used efficiently, reducing excess consumption and maximizing output. A well-integrated system from an Alabama robotics engineering company minimizes scrap by precisely measuring, cutting, and assembling components with unparalleled accuracy.

Traditional manufacturing methods often result in errors that require parts to be discarded or reworked, driving up costs. Robotics eliminate this issue by ensuring each action is executed flawlessly. Whether handling delicate components in electronics manufacturing or cutting metal with laser-guided precision, robots dramatically reduce waste, leading to healthier profit margins for businesses.

Robotics Reduce Equipment Wear, Cutting Replacement Costs Sharply

Frequent use of machinery without precision control leads to wear and tear, increasing maintenance costs and shortening equipment lifespan. Robotics operate with exact force, speed, and positioning, minimizing strain on mechanical parts. When businesses invest in automation through a robotics engineering company in Alabama, they extend the life of their equipment and lower the frequency of costly repairs and replacements.

By programming robots to handle high-impact or repetitive tasks, companies can reduce stress on conventional machinery. Automated systems distribute workloads evenly, preventing overuse of specific machines and reducing unexpected breakdowns. Over time, this translates to significant savings as businesses spend less on new equipment while maintaining peak operational efficiency.

Customized Robotic Integration Lowers Unexpected Downtime Expenses

Unplanned downtime is one of the biggest financial drains in any industry, leading to lost production time and missed deadlines. Robotics solutions tailored to specific workflows ensure seamless operation, reducing breakdowns and improving reliability. An Alabama robotics engineering company customizes automation systems to integrate smoothly with existing infrastructure, preventing costly interruptions.

With predictive maintenance features, robotics can detect early signs of wear and alert teams before failures occur. Automated systems also work around the clock without fatigue, preventing delays caused by human limitations. Companies that integrate robotics experience fewer production halts, keeping operations running smoothly while avoiding financial losses due to downtime.

Efficient Material Management by Robots Curbs Inventory Costs Significantly

Mismanaged inventory leads to wasted resources, overstocking, and lost revenue. Robotics streamline material handling, ensuring that inventory is tracked, stored, and used efficiently. A robotics engineering company in Alabama can implement automated systems that optimize material flow, reducing excess stock and preventing shortages that halt production.

Robots equipped with sensors and AI-driven tracking maintain real-time inventory control, allowing businesses to predict supply needs accurately. Instead of relying on manual stock counts or outdated tracking methods, companies benefit from precise inventory management. This level of efficiency reduces storage costs, prevents material spoilage, and ensures production runs without unnecessary supply disruptions.

Advanced Robotics Trim Staffing Overheads Without Compromising Output

Labor costs continue to rise, making workforce efficiency a priority for many businesses. While robotics don’t replace human ingenuity, they take over repetitive, physically demanding, and hazardous tasks, allowing employees to focus on higher-value work. An Alabama robotics engineering company helps businesses reduce labor expenses while maintaining high production levels.

Automated systems operate around the clock, eliminating the need for overtime wages or additional shifts. With robots handling precision tasks, businesses can allocate human workers to areas requiring problem-solving and oversight. This balance between automation and skilled labor leads to increased productivity without the burden of excessive staffing costs.

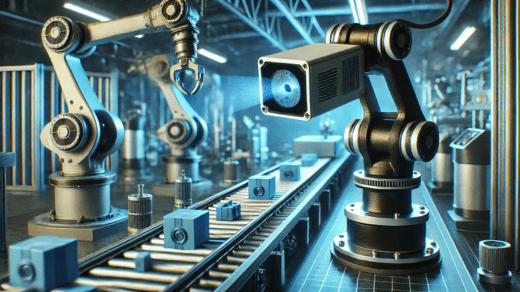

Automated Quality Control Catches Defects Early, Saving Rework Expenses

Detecting defects late in production can lead to expensive recalls, rework, and customer dissatisfaction. Robotics integrated with quality control processes ensure that every product meets strict standards before reaching the next phase. A robotics engineering company in Alabama can implement high-speed vision systems and AI-driven inspection robots that detect flaws in real-time.

Unlike human inspectors who may overlook subtle imperfections, robots analyze components with pinpoint accuracy. Automated quality control prevents defective products from moving further down the line, reducing waste and preventing costly corrections. By catching errors early, businesses save on labor, materials, and lost revenue, reinforcing the financial advantages of robotic automation.